By Sakshi Kapoor

Silk, a fabric well cherished for its shimmering appearance and its association with the higher social class and royalty throughout the history has also been providing livelihood opportunities to generations of families for a large section in Indian The fabric is named as Resham in northern parts of India and Pattu in southern states. Silk industry is an intrinsic part of the Indian Textiles Industry currently engaging more than 6 million workers in 300 textile mills and farms in Karnataka, Andhra Pradesh, West Bengal, Tamil Nadu, Assam, Manipur and Meghalaya producing around 23,000 tons of fabric every year. The figure is expected to rise up to 38,500 by the end of 2020.

The process of production of silk yarn initiates with female silk moth laying hundreds of eggs which are later stored and sold to the silkworm farmers. At the farm the eggs are kept under required temperature and humidity to eventually hatch into larvae or caterpillar. For near 40 days the caterpillars eat fresh mulberry leaves and then move inside their chambers to spin cocoons. This process is known as rearing of cocoon which is followed by the reeling process where the filament is carefully removed from the cocoon. This process of reeling of silk yearn is executed through a mix of traditional methods and modern techniques.

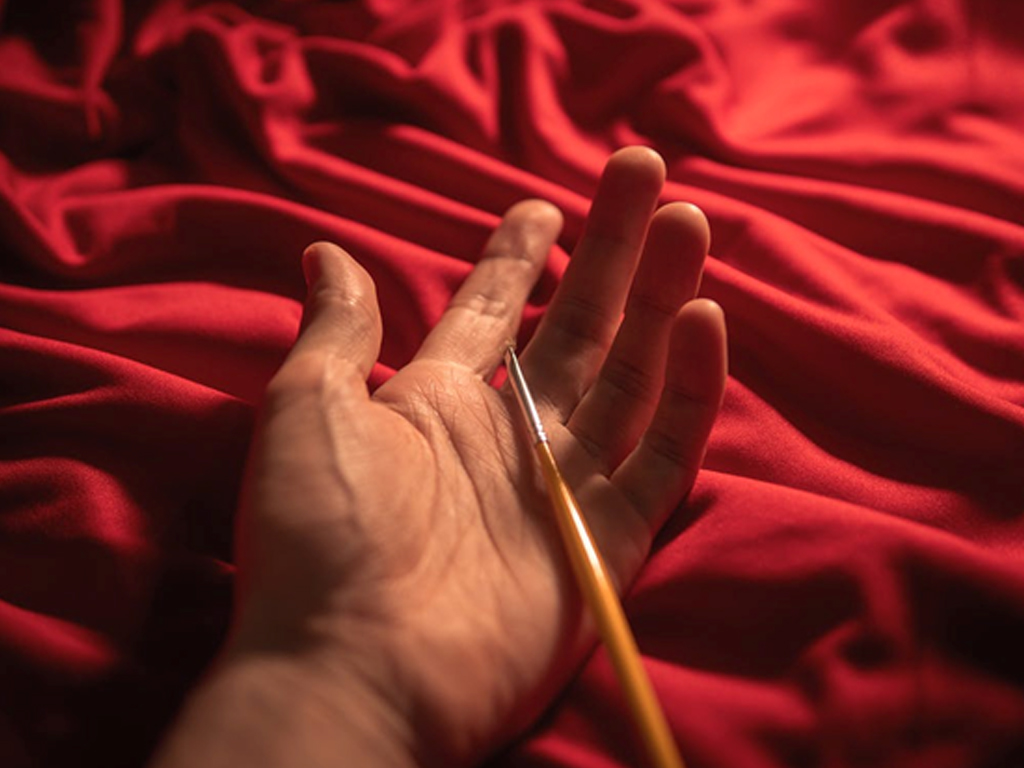

‘Thigh silk reeling’ is one such method used by the majority of women from different parts of India involved with silk reeling. Workers sit on the floor cross-legged, draw 5 to 6 filaments from cocoons on their thighs and twist it with left hand with a pinch of ash powder, oil and starch. It is a traditional as well as dated method involving high manual labor and uncomfortable, taxing process. The workers have frequently reported thigh and hand injuries (cuts and wounds) while reeling. Rural women are able to produce 70 grams of 70 denier yarn per day at best. The method is not just slow to and injurious but it also results in weak strength of the yarn. With the method, an average woman involved is able to earn only INR 125 per day.

To eradicate the dated practice of thigh silk reeling and to promote the profitable production of silk in India, Central Silk Technological Research Institute in association with an entrepreneur from Champa in Chhattisgarh has produced a machine which may help tribal women raise their profitability significantly avoiding the hazards associated with the occupation. A woman through Buniyaad Reeling Machine can produce 200 gms of silk yarn per day, increasing her income to up to Rs 350 per day. The machine can be powered by electricity or manually, by movement of the feet.

The Textiles ministry of India launched and distributed the Buniyaad silk reeling machine to the women associated with the Industry at Surging Silk Mega Event in New Delhi. The Textiles Minister said the Buniyaad reeling machine will not only help the women get rid of the painful practice of thigh reeling but also enhance their income and help them live a dignified life.