The world of textiles is a blend of art, science, and innovation. On 17th October 2024, this dynamic interplay came to life for students of JD Institute of Fashion Technology during their visit to the Technical Research and Development Center (TRADC) of Birla Cellulose in Kharach – Kosamba. This immersive experience offered a firsthand look at the intricate processes behind fiber-to-fabric transformation while highlighting the future of sustainable textile production.

The visit unfolded with a comprehensive walkthrough of the various stages in textile manufacturing. Students observed the transformation of fiber into yarn and its subsequent evolution into fabric through diverse techniques such as woven fabric production, circular knitting (single and double jersey), and flat knitting.

They were also introduced to the meticulous processes of dyeing and digital printing, where technology meets creativity to bring patterns and colors to life. Post-processing techniques like washing, singing, and drying further demonstrated the steps required to refine and perfect fabric quality, making it ready for use in fashion and design.

An exciting highlight of the visit was the exploration of TRADC’s Yarn and Fabric Testing Labs, equipped with state-of-the-art technology for ensuring the highest standards of quality. Students were shown various testing methods for measuring strength, thickness, density, and composition, offering a deeper understanding of how each parameter impacts the final product.

Special attention was given to tests for color fastness and wash durability, critical factors that determine the reliability and lifespan of textiles. These hands-on demonstrations gave the students a clear sense of how rigorous quality checks are integral to professional textile production.

Sustainability stood out as a recurring theme throughout the visit. Led by Mr. Abir Chakrobarty, the TRADC team shared insights into Birla Cellulose’s eco-conscious initiatives, including efforts to reduce carbon footprints and develop mechanically recycled products.

The emphasis on sustainability not only aligned with current industry trends but also inspired students to think about integrating environmentally responsible practices into their future designs. It was a valuable lesson in how creativity and responsibility can coexist to shape a better future for the fashion industry.

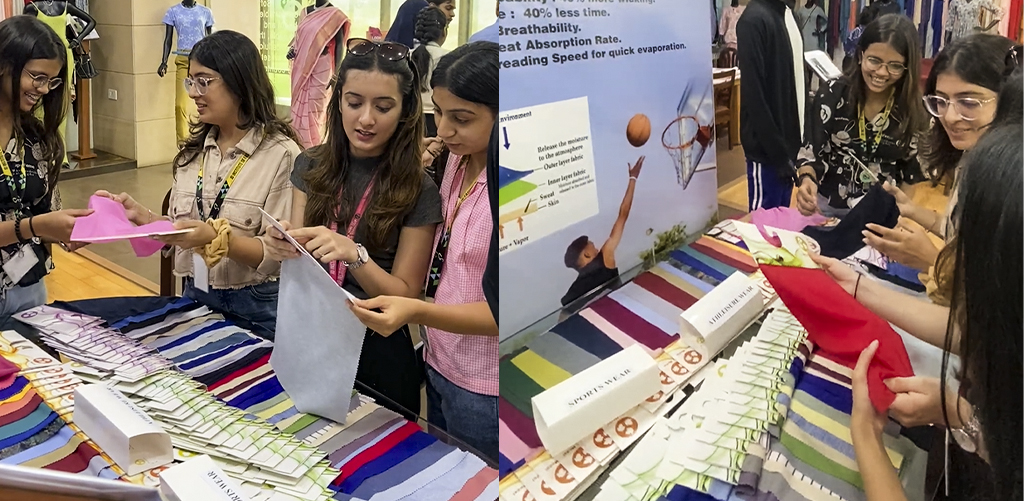

The journey concluded in the Design Room, a hub of innovation where students saw the artistic potential of yarns transformed into unique and sustainable textile creations. This space bridged the technical aspects of textile manufacturing with the creative possibilities that drive design.

For the students, this segment was particularly impactful, showcasing the power of combining technical expertise with artistic vision. It encouraged them to think beyond traditional design boundaries while keeping sustainability at the forefront.

The visit to TRADC provided JD Institute students a comprehensive insight into the textile manufacturing process, encompassing fibre to finished product. Every phase of the process, from examining manufacturing procedures to comprehending quality control measures and investigating sustainable practices, provided insights that transcended textbooks and classroom discourse.

The visit provided students with practical tools and motivation for their future in fashion and design by integrating technical knowledge with sustainability and creativity. Such experiences emphasise the significance of industry exposure in developing well-rounded professionals capable of making important contributions to the dynamic textile sector. Through initiatives like this, JD Institute of Fashion Technology continues to uphold its commitment to fostering innovation, quality, and sustainability in the field of design education.