What if your next outfit didn’t need fabric, scissors, or even a tailor?

Imagine just plugging in your measurements, hitting ‘print,’ and boom — a custom-made jacket ready in hours, with zero waste. Welcome to the world of 3D printing in fashion. It’s fast, sustainable, and about to flip the entire fashion industry upside down.

If you’re serious about building a future-ready brand, this is the technology to understand. In fact, smart courses like the Fashion Business Management program at JD Institute of Fashion Technology are already teaching it. Because staying ahead means learning beyond the basics.

Let’s break down exactly how 3D printing is revolutionizing fashion manufacturing & reducing waste — and why it’s your ticket to staying ahead in the game.

3D printing lets designers create pieces that are literally made for your body. Using 3D body scans, clothes can be printed to your exact size — no leftover fabric, no wrong fits, no returns. That’s a big win for both the customer and the planet.

Startup Spotlight: Danit Peleg

This designer went viral after she created an entire fashion collection from home using 3D printers. Her dream? That someday, you’ll be able to download her dress design and print it at home. It’s like the Netflix of fashion — but way cooler.

Old-school fashion methods waste about 15% of fabric just during the cutting stage. 3D printing changes the whole process — it builds garments layer by layer using only the material needed. No scraps. Some brands are even using recyclable and plant-based materials like PLA, cutting down the environmental impact even more.

Startup Spotlight: Ministry of Supply

This Boston-based brand uses 3D knitting machines to make seamless, waste-free clothing. They’ve even printed flexible suits that move with your body. Stylish and smart.

And yes, this is the kind of innovation you’ll dive into during the Fashion Business Management course at JD Institute — it’s not just about what’s trendy, but what’s transformational.

Fashion has a huge overproduction problem. Tons of clothes go unsold and end up in landfills. But with 3D printing, designers can create small batches or even one-off pieces, testing new ideas without needing giant inventories or warehouses.

Startup Spotlight: ZER Collection (Spain)

ZER uses 3D printing and zero-waste design techniques to create futuristic garments in small runs. They’re redefining fashion timelines by creating only what’s needed, when it’s needed.

If you’re planning to launch your own brand, 3D printing gives you the power to start small, stay flexible, and waste less.

3D printing speeds up the design-to-production process like never before. Designers can quickly test ideas, print samples, tweak details, and go straight to production. That’s a game-changer in a world where trends change faster than ever.

Startup Spotlight: VOJD Studios (Germany)

VOJD works with luxury fashion houses like Alexander McQueen and Dior to design 3D-printed accessories. With rapid prototyping, they help big brands keep up with creativity — without delays or wastage.

This is also why fashion business students at places like JD Institute learn to blend creativity with tools like 3D modeling and digital fabrication. Because dreaming big is great — but building smart is better.

The future of fashion might not be about selling clothes, but selling files. With 3D printing, designers can sell downloadable clothing designs that customers print themselves or at local hubs. It’s fashion without shipping, packaging, or storage.

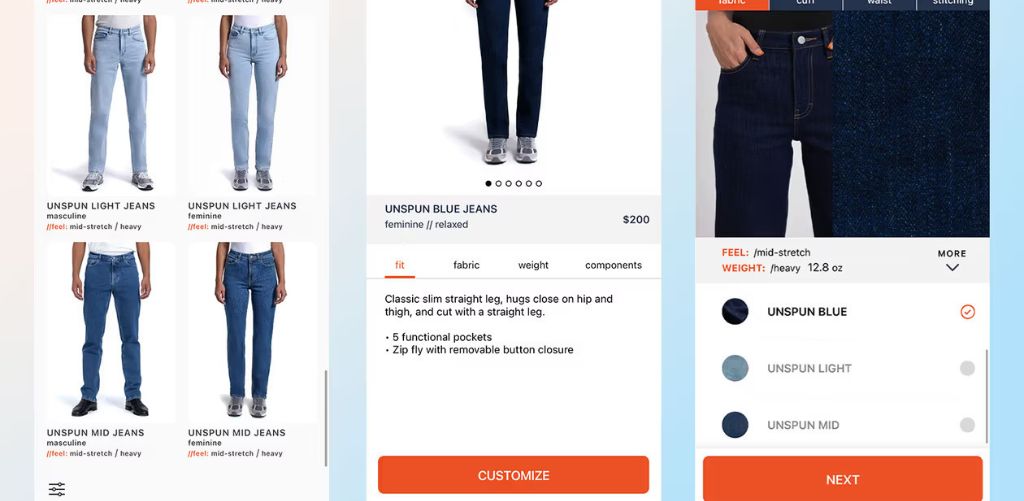

Startup Spotlight: Unspun

This U.S.-based brand 3D-weaves custom-fit jeans after scanning the customer’s body. Their tech-driven model focuses on local, on-demand production — no bulk shipping, no excess stock, no waste.

For the modern fashion entrepreneur, this opens up brand new ways to reach customers, cut costs, and stay eco-conscious.

Fashion is changing fast — and 3D printing is one of the biggest reasons why. It’s helping designers reduce waste, create faster, and think smarter. If you’re dreaming of starting your own brand or running a sustainable label, this is your wake-up call.

Learn the tech. Design the change. And if you’re serious about being a fashion entrepreneur, check out the Fashion Business Management course at JD Institute.